| Sign In | Join Free | My carsrow.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My carsrow.com |

|

Brand Name : Antaeus

Model Number : AD-M002

Certification : /

Place of Origin : Hunan,China

MOQ : Negotiation

Price : Negotiation

Payment Terms : T/T or Negotiation

Supply Ability : Full Supply

Delivery Time : 15-45 days

Packaging Details : Inner vacuum packaging, outside carton.

Product Name : Microwave Magnetron Ceramic

Material : 95% aluminum oxide

Density : 3.7g/cm3-5.9g/cm3

High Light : Microwave Magnetron Ceramic / Ceramic Ring / Metallized Ceramic

Power Range : ≤7W /cm2

Working Temperature : -40℃-125℃

Application : Microwave Magnetron Ceramic for Home Electrical Appliances

Working Voltage : 3v~480v

Thermal Shock Test : 1.(Temperature):-55℃/125℃ 2,(Time)2.2min 3 (Switching time ) Max 10s 4 (Frequency):15 times

Working Life : >5000 h

Alumina Magnetron Ceramic / Ceramic Parts for Home Electrical Appliances

1. Description:

Alumina Magnetron Ceramic is a very hard ceramic that is excellent at resisting abrasion and is ideal for wear-resistant inserts or products. It is commonly used as a high temperature electrical insulator, particularly the higher purity grades which offer better resistivity. It also offers good resistance to strong acids and alkalis at elevated temperatures, which makes it ideal for applications where resistance to corrosive substances is required. Some common applications include:

2. Feature Advantages:

1) High elasticity modulus

2) High compressive strength.

3) Anti corrosion

4) Abrasion resistance

5) Impact resistance

6) High precision

7) High stability

8) Good advanced ceramic materials

9) High welding sealing performance

10) High hardness and high density

11) Low thermal conductivity

12) Chemical inertness

13) Good wear resistance

14) High Fracture toughness

15) Good insulation performance

16) High temperature resistance

3. Material Features / Properties:

| Color | White or Ivory | White or Ivory | White or Ivory | |

| Density | g/cm 3 | 3.82 | 3.9 | 3.92 |

| Hardness | HRA | 83 | 85 | 85 |

| Flexural Strength | Mpa (psi*10 3 ) | 375 | 386 | 381 |

4. Technical Parameters:

| Technical Parameters of Ceramics | ||||||||

| Items | Test Conditions | Unit or Symbol | 99% AL2O3 | 95% AL2O3 | 90% AL2O3 | Zirconia | Steatite | Silicon Carbide |

| Volume Density | -- | g/cm3 | ≥3.70 | ≥3.62 | ≥3.40 | ≥5.90 | ≥2.60 | ≥3.08 |

| Tightness | -- | Pa·m³/s | ≤1.0×10-11 | ≤1.0×10-11 | ≤1.0×10-11 | - | - | - |

| Liquid Permeability | -- | -- | Pass | Pass | Pass | Pass | - | |

| Flexural Strength | - | MPa | ≥300 | ≥280 | ≥230 | ≥1100 | ≥120 | ≥400 |

| Elastic Modulus | - | GPa | - | ≥280 | ≥250 | ≥220 | - | 400 |

| Poisson Ratio | - | - | - | 0.20~0.25 | 0.20~0.25 | - | - | - |

| Thermal Shock Resistance | 800℃( Room Temperature) Cycle: 10 times | Pass | Pass | Pass | - | - | - | |

| Coefficient of Linear Expansion | 20℃~100℃ | ×10-6 K-1 | - | - | - | ≤8 | - | |

| 20℃~500℃ | ×10-6 K-1 | 6.5~7.5 | 6.5~7.5 | 6.5~7.5 | 6.5~11.2 | - | - | |

| 20℃~800℃ | ×10-6 K-1 | 6.5~8.0 | 6.5~8.0 | 6.3~7.3 | - | 4 | ||

| 20℃~1200℃ | ×10-6 K-1 | - | 7.0~8.5 | - | - | - | - | |

| Coefficient of Thermal Conductivity | 20℃ | W/(m·k) | - | - | - | - | - | 90~110 |

| 1000℃ | ||||||||

| Dielectric Constant | 1MHz 20℃ | - | 9.0~10.5 | 9.0~10 | 9.0~10 | - | ≤7.5 | - |

| 1MHz 50℃ | - | - | 9.0~10 | - | - | - | - | |

| 10GHz 20℃ | - | 9.0~10.5 | 9.0~10 | 9.0~10 | - | - | - | |

| Volume Resistivity | 100℃ | Ω·cm | ≥1.0×1013 | ≥1.0×1013 | ≥1.0×1013 | - | ≥1.0×1012 | - |

| 300℃ | ≥1.0×1013 | ≥1.0×1010 | ≥1.0×1013 | - | - | - | ||

| 500℃ | ≥1.0×109 | ≥1.0×108 | -- | - | - | - | ||

| Disruptive Strength | D.C | kV/mm | ≥17 | ≥15 | ≥15 | - | ≥20 | - |

| Chemical Durability | 1:9HCl | mg/c㎡ | ≤0.7 | ≤7.0 | - | - | - | - |

| 10%NaOH | mg/c㎡ | ≤0.1 | ≤0.2 | - | -- | - | - | |

| Grain Size | - | μm | - | 3~12 | - | - | - | - |

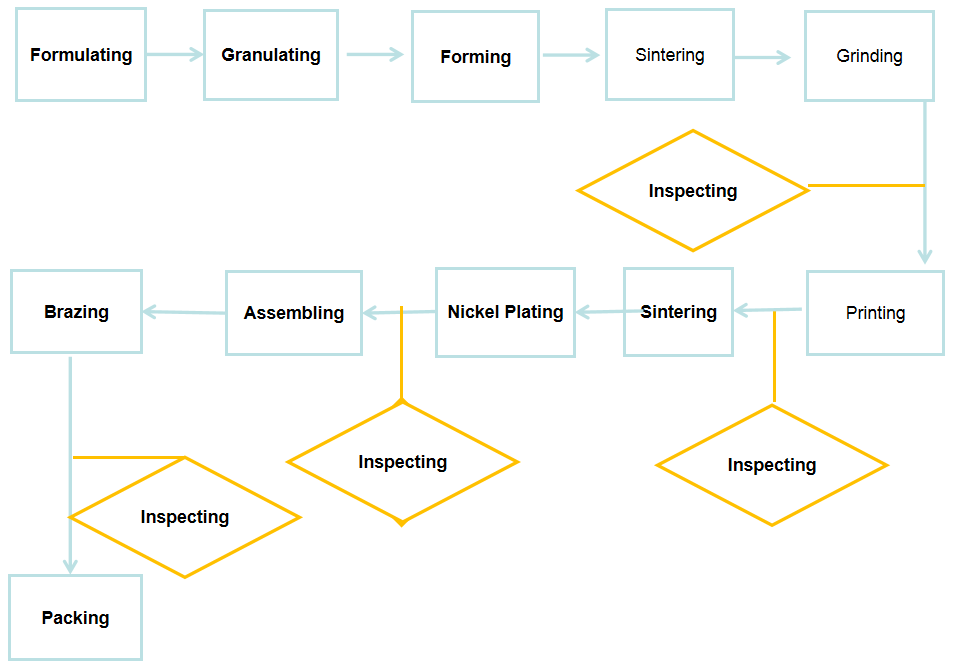

5. Process Flows:

Formulating --- Granulating --- Forming --- Sintering --- Grinding --- Printing --- Nickel Plating --- Inspecting --- Packing

6. Application Fields:

Microwave Magnetron Ceramic for Home Electrical Appliances , Aerospace and Other Industry!

7. Production Facilities: Prilling Tower , Forming Machine , High Temperature Sintering Kiln

8. Detection Devices:

Electric Performance Tester , Film Thickness Analyzer , Granulometer , Helium Mass Spectrometer Leak Detector , Universal Pull Force Meter

9. Notes:Above information only for reference and please contact with us for more details freely when you have any inquiry!

|

|

Magnetron 95 Alumina Ceramic Anti Corrosion Images |